Digital transformation in engineering provides a route to resilience.

Organizations like General Electric that have undergone transformations can effectively navigate crises. The reason is independent of past decisions or strategic gambles. It is thanks to well-designed transformations that flourish amidst evolving circumstances.

In addition to improving efficiency, efficacy, and value, an effective digital transformation in your engineering company can cut expenses through prudent investments.

It can promote widespread innovation, provide engineers with supplementary skills, and preserve essential talent. Technology adoption strategies offer an effective way to achieve this process.

Scroll down to learn everything you need about a digital transformation in engineering, beginning with a definition. Then, move on to its impact and objectives.

Next, come examples with learning points and insightful benefits and challenges.

So, let’s get started and help you retain talent, acquire the right technologies, and nurture a culture of innovation as your staff learns new digital transformation skills.

- What is digital transformation in engineering?

- What are examples of digital transformation in engineering?

- What is the impact of digital transformation in engineering?

- What are the main objectives of digital transformation in engineering?

- What are the benefits of digital transformation in engineering?

- What are the challenges of digital transformation in engineering?

- Nurture a culture of innovation with your transformation

What is digital transformation in engineering?

Digital transformation in engineering incorporates digital technology into every element of a business. Organizations do this to enhance processes and efficiency.

For example, a construction company might utilize 3D modeling software for digital designs or drone technology for site surveys, substituting traditional manual methods and thus enhancing efficiency and precision.

What are examples of digital transformation in engineering?

It’s one thing to talk about the goals of digital transformation. But now we need to see this knowledge in action. Here are three examples of digitalization in engineering and construction settings. They have learning points to inspire your transformation successes.

Learn from them to discover how to understand and control the variables of digital adoption for new technologies.

Arup: CSDI Platforms

Sustainable development engineering organization Arup views smart cities as one of their most valuable tools for urban development.

A key smart city initiative is developing a Common Spatial Data Infrastructure (CSDI) and a geospatial lab for data exchange as part of their data transformation. In 2020, the Planning Department (PlanD) commissioned Arup, a trusted government advisor, to study creating a Building Environment Application Platform (BEAP) using CSDI.

The BEAP platform would be a ‘Centre of Excellence’ for built environment apps. It would encourage collaboration and promote sharing of best practices. It would be like an ‘App Store.’ and offer apps for city planning, infrastructure, engineering, and the environment.

The study used CSDI’s spatial data and presented ten digital applications. These applications let users search for, interact with, and download them via a web portal. This technology will let stakeholders use a digital twin approach for planning, management, and operations. It will support Hong Kong’s innovative city development.

The APIs connect to other data sources from the CSDI platform. They process and enrich datasets to support the apps. Security is key to our system. It’s important at both the network and app levels.

What can you learn from this example?

We can learn several lessons from Arup’s transformation, including:

- Leverage Spatial Data: Utilize CSDI for comprehensive data integration to enhance city planning and infrastructure projects.

- Enable Digital Twins: Implement digital twin technology to improve real-time decision-making and project management.

- Develop User-Friendly Platforms: Create accessible web portals to facilitate application use, fostering stakeholder engagement and collaboration.

Arcadis Netherlands: Performance-based maintenance

In the early 2000s, the Dutch railway system faced challenges. Failure rates rose, punctuality fell, operational expenses rose, and customer satisfaction fell due to performance issues.

Asset owners aimed to save resources. They also aimed to improve resilience.

Arcadis, partnering with Dura Vermeer under Asset Rail, introduced a performance-based maintenance approach. Arcadis experts devised methodologies to predict failures and optimize interventions, resulting in sustained improvements over 15 years.

By understanding asset performance needs, Arcadis tailors maintenance strategies to maximize effectiveness. Based on risk analysis, this approach schedules interventions based on traffic levels, optimizing resource usage and customer satisfaction.

Notably, this approach led to a 64% reduction in technical failures and a 40% decrease in maintenance costs nationwide. Critical failures are now repaired within an hour on average, with 40% predicted in advance, allowing timely preventive maintenance.

Arcadis oversees maintenance for 30% of the Dutch railway network, significantly enhancing performance.

What can you learn from this example?

We can learn several lessons from Arcadis’s transformation, including:

- Embrace Performance-Based Maintenance: Shift from descriptive to predictive maintenance for improved efficiency and effectiveness.

- Leverage Data Analytics: Utilize predictive analytics to anticipate failures and optimize maintenance interventions.

- Tailor Maintenance Strategies: Customize maintenance plans based on risk analysis and asset performance requirements.

ArborXR: VR engineer employee training

VR training has quickly become a key tool for workforce development. Engineering organizations use it. Learning through VR, AR, and MR is immersive. It offers new ways for employees to gain and strengthen vital skills.

Delta Air Lines is leading this charge, having partnered with VR solutions providers like Futurus and ArborXR to spearhead enterprise VR training adoption. Delta has integrated VR training for deicing aircraft technicians, yielding substantial savings in annual training costs while markedly enhancing efficiency and efficacy.

Before, only three technicians could train each day. With VR, over 150 technicians now receive Delta’s training daily. After initial training, trainers conduct VR proficiency checks. They compare them to live tests.

Traditionally, Delta faced challenges during deicing training. This issue was due to weather and the high cost of de-icing fluid.

But VR training with Futurus has changed this. Delta’s VR program, launched in 2022, has significantly bolstered technicians’ skills development and delivered transformative outcomes for the company.

Delta’s VR training initiative increased daily checks from 3 to 150, a nearly 5,000% surge. Reducing fluid usage and travel expenses also generated millions in operational cost savings.

It also simplified training by cutting travel and boosting trainee confidence with realistic practice scenarios. However, these benefits weren’t enough to justify the ROI. The transformation also provided insights via LMS integration, including usage rates and pass rates.

What can you learn from this example?

We can learn several lessons from ArborXR’s transformation, including:

- Embrace Technological Innovation: When you incorporate VR training, you enhance efficiency, cost-effectiveness, and skill development in your organization.

- Prioritize Employee Development: It is helpful to invest in immersive training solutions to optimize workforce proficiency and the confidence of your employees.

- Reduce costs with VR training: VR reduces training costs by minimizing the need for physical materials, travel, and downtime.

Consider all these examples, incorporating technologies like CSDI platforms, performance-based maintenance, and VR training. Could you apply similar technologies in similar ways? Or do they inspire you to consider new approaches to existing challenges?

Consider successful industry examples of engineering organizations’ digital transformations to inspire your transformation initiatives.

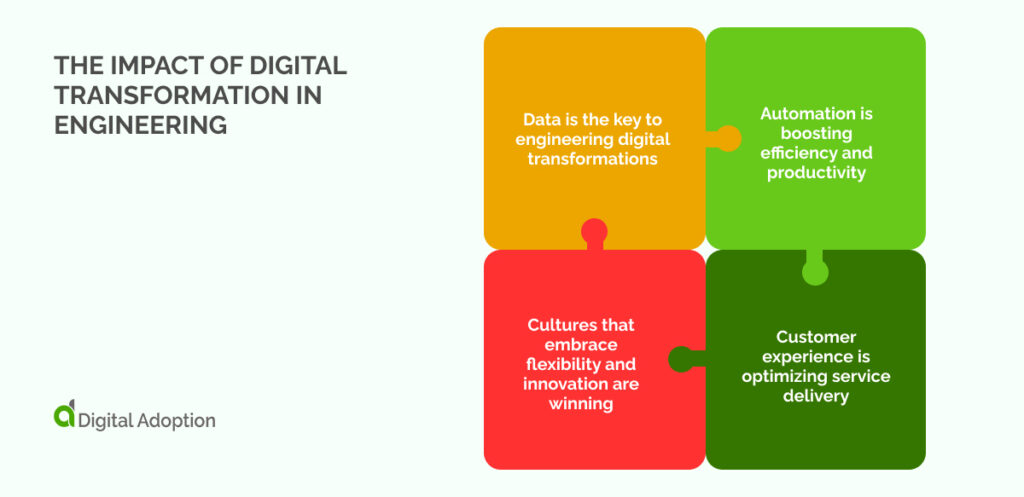

What is the impact of digital transformation in engineering?

The impact of effective digital transformation in engineering is immediately visible. Data is king, and when analysts use data correctly, efficiency increases, and customer service experiences are positive. These impacts lead to a successful company and higher revenue.

The ways digital transformations affect engineering include:

- Data has become the key to engineering digital transformations.

- Automation is boosting efficiency and productivity.

- Customer Experience is optimizing service delivery.

- Cultures that embrace flexibility and innovation are winning.

Data is the key to engineering digital transformations

In the age of digital transformation, data reigns supreme. For engineering firms, it offers critical insights into diverse operational aspects.

Machine learning algorithms and AI can process and analyze these extensive datasets, facilitating predictive analytics, better decision-making, and innovative solutions.

In the aerospace industry, for example, data from sensors embedded in machinery or equipment can predict maintenance requirements or detect potential safety issues before they escalate into significant problems.

Automation is boosting efficiency and productivity

Digital transformation in engineering goes hand in hand with automation. Engineering companies can significantly boost productivity and efficiency by leveraging digital technology to automate repetitive manual tasks.

For instance, in the automotive industry, AI-driven robotics are extensively employed on assembly lines to accelerate production and enhance precision.

Similarly, in the construction sector, digital tools can automate various facets of project management, streamline workflows, and improve coordination.

Customer experience is optimizing service delivery

Digital transformation in engineering also revolutionizes how companies engage with their clients. With the advent of digital platforms, clients now expect swift, efficient, and transparent service delivery.

Digital tools enhance communication, enable real-time updates, and offer predictive insights, which can significantly improve the client experience.

For example, in the rail industry, digital platforms can deliver real-time project progress updates to all stakeholders, minimizing miscommunication and boosting transparency.

Cultures that embrace flexibility and innovation are winning

One of the most challenging aspects of digital transformation is driving cultural change within the organization.

Engineering companies must cultivate a culture that promotes innovation, embraces new technologies, and fully adapts to change to harness the benefits. This process may involve investing in upskilling employees, fostering a more collaborative work environment, or adopting flexible operational structures.

What are the main objectives of digital transformation in engineering?

A digital transformation in engineering has several objectives. It’s essential to be aware of these to ensure you are always on the right track and on your way to achieving ROI.

Improve efficiency

Digital transformation in engineering aims to streamline workflows and processes using digital tools to boost productivity and minimize wasted time. Companies can optimize their operations by integrating automation, data analytics, and project management software.

Automation reduces the need for repetitive manual tasks, allowing engineers to focus on more complex and creative aspects of their work.

Data analytics provides insights that help identify bottlenecks and inefficiencies, leading to more informed decision-making. Project management software ensures better coordination and resource allocation, reducing delays and errors.

These improvements lead to faster project completion times and increased operational efficiency.

Optimize accuracy

Implementing advanced technologies like 3D modeling and simulations is crucial for ensuring precise and reliable outcomes in engineering projects. 3D modeling software allows engineers to create detailed and accurate representations of structures and components, facilitating better design and planning.

Simulations enable the testing of different scenarios and conditions, predicting how materials and structures will behave under various stresses and loads. This action reduces the likelihood of errors and rework, saving time and resources.

Digital tools enhance accuracy and help deliver high-quality projects that meet stringent safety and performance standards, ultimately increasing client satisfaction and trust.

Unlock innovation

Digital transformation fosters creativity and innovation by providing platforms that encourage experimentation and the development of new solutions.

Digital tools like CAD software, virtual reality, and cloud-based collaboration platforms enable engineers to explore innovative design concepts and collaborate in real-time, regardless of geographical location.

These technologies provide a sandbox environment where engineers can test and refine ideas without the constraints of traditional methods.

By embracing digital transformation, engineering companies can stay ahead of the competition and deliver cutting-edge solutions to their clients.

Increase safety

A key objective of digital transformation is to enhance safety in engineering projects by using predictive maintenance and real-time monitoring systems.

Predictive maintenance leverages machine learning algorithms to anticipate equipment failures before they occur, allowing for timely repairs and preventing accidents.

Real-time monitoring systems track the performance and condition of equipment and structures, providing immediate alerts to potential safety hazards. These technologies help identify risks early, enabling proactive measures to mitigate them.

Digital transformation increases safety, protects the workforce and assets, and ensures compliance with regulatory standards, reducing the likelihood of costly fines and legal issues.

Promote a collaborative culture

Digital transformation aims to enable seamless communication and teamwork across different locations through advanced collaboration tools. Cloud-based platforms, video conferencing, AI productivity tools, and project management software allow teams to work together effectively regardless of their physical location.

These tools help share information in real-time, solve problems, and work on projects together. Better collaboration leads to aligned project goals, faster decision-making, and more agility in responding to changes.

Digital transformation breaks down geographical barriers. It lets engineering teams use diverse expertise and views. This drive leads to better project results. It also fosters teamwork and innovation.

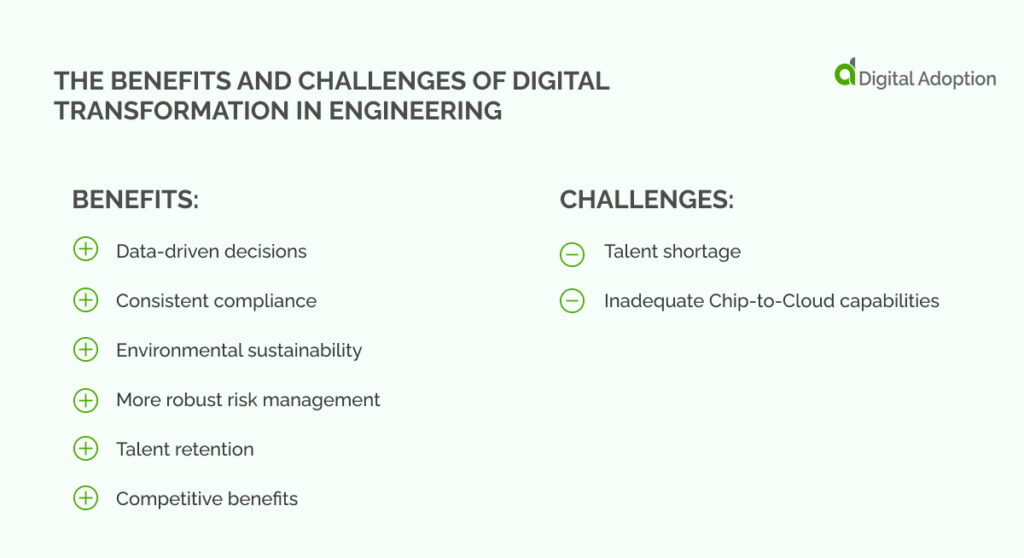

What are the benefits of digital transformation in engineering?

Digital transformations in engineering have many benefits. Otherwise, companies wouldn’t spend millions on them, right?

Consider these benefits and use them to decide if you need a transformation.

Data-driven decisions

Digital transformation equips engineering firms with real-time data and analytics, empowering informed decision-making.

Data insights help companies understand operations. This data helps them find trends, foresee challenges, and seize opportunities to grow.

This data-driven approach lets firms make quick choices. They are smart. It improves projects and efficiency. It drives business success. It also gives a competitive edge in a fast-changing industry.

Consistent compliance

Digitalization helps engineering organizations. It lets them ensure strict adherence to rules from regulators and the industry. Digital tools make compliance easier. They centralize documents and provide real-time monitoring. This advantage cuts the risk of non-compliance and penalties.

By following regulations, companies protect their reputation. They also keep the trust of stakeholders.

Automated checks and audits ensure all operations meet the standards. They boost accountability and operational integrity.

Environmental sustainability

Digital transformation lets engineering firms use resources better. It also helps them cut their carbon footprint.

Companies can monitor energy use and cut waste. They can also optimize resource use by using sustainable practices and digital tech. Examples include IoT sensors and data analytics.

This approach helps the environment, boosts corporate social responsibility efforts, and positions firms as leaders in sustainable engineering.

Sustainable operations can also save costs. They can also improve brand reputation.

More robust risk management

Digitalization improves risk management. It gives engineering firms many data insights. Advanced analytics and predictive modeling help companies better find and assess risks, which in turn helps them make plans to avoid them.

Organizations can use digital tools to assess and monitor risk. This can cut the chance of bad events. It protects assets and keeps the business running.

This proactive risk management maintains stability. It reduces surprises.

Talent retention

Embracing digital transformation helps engineering firms attract and retain top talent by providing access to new technology and new work environments.

Companies can empower employees by investing in digital skills training and offering chances for professional development. They can help them thrive in a digital-centric workplace.

This approach promotes a culture of innovation, creativity, and learning. It boosts employee happiness and retention.

A forward-thinking approach to talent management ensures that firms remain competitive in attracting skilled professionals.

Competitive benefits

By embracing digital innovation and transformation, engineering firms can gain a big edge and become more competitive in the market. Digitalization lets companies streamline operations, speed up project delivery, and add value for clients.

By leveraging digital tools for product innovation, process optimization, and customer engagement, organizations can differentiate themselves from competitors, attract new business opportunities, and position themselves as industry leaders.

Staying at the front of technology ensures growth in the long term. It also provides market relevance.

What are the challenges of digital transformation in engineering?

Digital changes are hard in any industry, and the rewards are always hard-won.

The sector faces challenges for a successful digital transformation. These include talent shortages, not enough Chip-To-Cloud capabilities and partners, and too small development budgets.

The good news? Learning more about these challenges can help you beat them.

Talent shortage

Enterprises must acquire top talent to stay ahead in next-gen engineering. Experts project the creation of nearly 149 million new digital roles by 2025. However, the engineering industry, like others, faces a talent shortage.

Companies must reconsider their engineering recruitment strategies. Consider competing against major tech giants. They include Google, Facebook, Tesla, and Apple. They are known for their high pay and focus on engineering talent.

Engineering is crucial to the organization. It happens when technologists have senior positions. This environment attracts top talent.

Inadequate Chip-to-Cloud capabilities

Experts predict a surge in Chip-to-Cloud capabilities. This step will create opportunities, but it will also bring challenges for current enterprises. Digital engineering finds a promising avenue in chip-to-cloud solutions. It improves IoT adoption by improving security and cutting energy use.

Newer players in automotive and other sectors compete a lot with traditional organizations. They have advanced chipsets, autonomous driving algorithms, and cloud capabilities.

Transitioning to Chip-to-Cloud will require reskilling employees accustomed to traditional digital engineering practices. To stay competitive, companies must invest in training current staff. They must also hire new pros. They must have Chip-to-Cloud expertise.

Engineering Research & Development (ER&D) budgetary constraints

Despite the push for next-generation digital engineering, enterprises face pressure to manage their ER&D budgets efficiently. Due to a lack of internal expertise, many companies are outsourcing, with predictions stating that the global engineering R&D outsourcing market will reach USD 400 billion by 2031.

Budget limits vary by industry. They prompt organizations to cut old engineering budgets, but they also prompt them to allocate resources for new products and technologies.

Despite these challenges and the waste from hiring ER&D experts externally. But, many CFOs plan to increase tech budgets. They see digital engineering as key. It fights inflation and drives growth.

Reliable partners gap

Enterprises rely more on reliable partners who help them navigate digital complexity. The pandemic underscored the importance of streamlined project management and efficient engagement models.

Partners offer cost savings and seamless help. They help with portfolio growth and digital transformation. They meet the need for efficient project management and lower costs.

As you can see, the benefits of an engineering transformation come only with hard work. You have to overcome the challenges.

However, this knowledge makes it easier to succeed and reap the rewards. You will learn about your organization’s challenges and the benefits that drive your progress.

Nurture a culture of innovation with your transformation

There are many benefits to nurturing a culture of innovation. You do this as you implement a transformation. Data drives your decisions, and efficiency improves alongside environmental sustainability. But these rewards are not easy to win.

When your staff embraces a digital transformation in engineering, they gain skills. These skills lead to a culture of innovation. They can then more easily integrate cutting-edge technologies and modern practices.

Encouraging continuous learning and collaboration empowers employees. It lets them explore new ideas and develop creative solutions.

Companies can boost creativity and drive growth by giving employees access to advanced digital tools and investing in skill training.

This new place improves efficiency. It positions firms as industry leaders. They are ready to tackle future challenges.