Companies now use digital tools like computerized maintenance management systems (CMMS) to keep their equipment running smoothly. These systems help track when machines need repairs and catch problems before they get serious.

Businesses can now monitor their machines in real time using sensors and mobile apps. They can see what’s happening and fix problems before they break down.

Artificial intelligence (AI) makes CMMS tools even more helpful. It can analyze data and predict when a device might need maintenance. As technology becomes more sophisticated, CMMS helps companies stay competitive and keep instruments working at their best.

This article explores CMMS, how it works, its differences from EAM, the role of AI, and the industries that use it.

- What is a computerized maintenance management system (CMMS)?

- How does a computerized maintenance management system (CMMS) work?

- What is the difference between CMMS and enterprise asset management (EAM)?

- How is AI used in a CMMS?

- Industries that use CMMS software

- What to look for in an ideal CMMS?

- A future outlook on CMMS

- People Also Ask

What is a computerized maintenance management system (CMMS)?

A Computerized Maintenance Management System (CMMS), also known as a Computerized Maintenance Management Information System (CMMIS), uses centralized software to manage and optimize maintenance operations, ensuring the reliability of critical business assets.

Common in industries reliant on physical equipment such as factory machinery, IoT devices, smart robotics, and vehicles, CMMS schedules repairs, tracks equipment performance, and reduces downtime by organizing work orders, resources, and labor in one centralized location.

With the adoption of AI, CMMS systems have evolved to use data more proactively and agilely. Real-time analysis through AI of critical software, hardware, and infrastructure enables CMMS to intersect increasingly with predictive maintenance methods.

According to McKinsey, predictive maintenance strategies implemented via CMMS can reduce downtime by 30–50% and extend machine life by 20–40%, highlighting the significant impact of these technologies on maintenance efficiency.

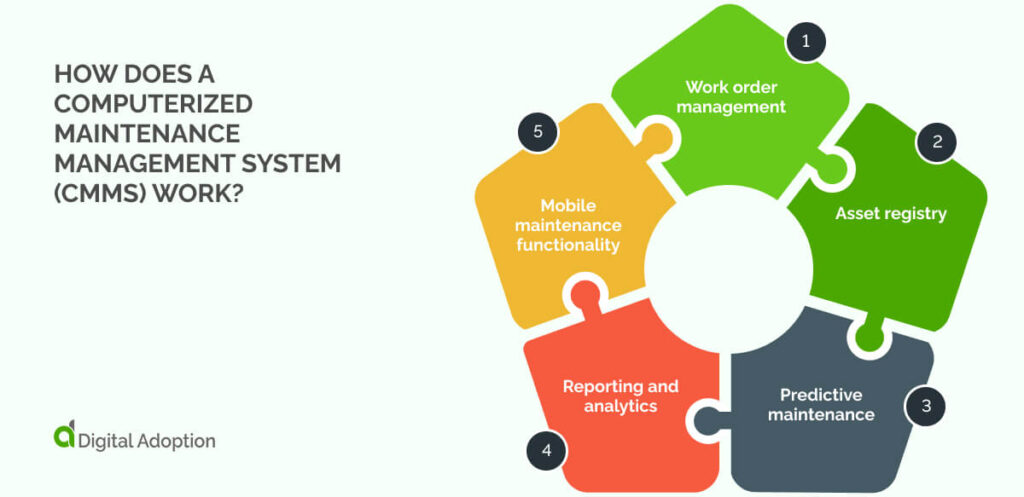

How does a computerized maintenance management system (CMMS) work?

Now that we have a basic understanding of a CMMS, let’s get into the detail of how it works—more specifically, the key functions it excels at.

Let’s take a closer look:

Work order management

CMMS allows teams to design and deploy work orders. When maintenance is needed, a work order is made. It retains details like the order type, problem descriptions, and priority solutions. It offers teams a centralized place to assign work to the right person and track progress. This minimizes workflow disruptions and ensures deadlines are reached.

Asset registry

CMMS house key asset information. This includes information about each asset’s condition, type, and maintenance history. For software, it tracks the version and updates. Having all this information in one place helps teams manage assets and plan for future needs.

Predictive maintenance

CMMS uses data to predict when maintenance is needed. It monitors IT asset management and performance and looks for signs of wear. For software, it tracks usage and errors. Predictive alerts help prevent issues before they happen, reducing downtime.

Reporting and analytics

CMMS generates reports on maintenance activities. It tracks work order completion, asset performance, and costs. Analytics help managers see how well maintenance is going. Reports can focus on software metrics, like error rates or system performance, helping improve software quality.

Mobile maintenance functionality

CMMS includes mobile features for easy access. Technicians can view work orders, asset details, and updates on their phones, making it easier to manage tasks and make fixes from anywhere. For software, mobile access allows teams to update or fix issues on the go.

What is the difference between CMMS and enterprise asset management (EAM)?

CMMS functions overlap with another commonly used asset management solution—enterprise asset management (EAM).

EAM borrows foundational elements from CMMS functions to create a more comprehensive solution for enterprise needs. These systems usually encompass a broader suite of management services leveraged across an asset’s entire lifecycle.

EAM systems ensure governance, risk, and compliance, manage software ROI, and streamline asset procurement and disposal. They integrate well with other enterprise tools for better control of key assets.

To better understand how CMMS and EAM work, let’s delve into some of their distinct differences below:

| Feature | CMMS | EAM |

| Primary focus | Maintenance management and work order tracking | Comprehensive asset lifecycle management |

| Scope | Focused on maintenance tasks and scheduling | Broader, including procurement, compliance, and retirement |

| Asset coverage | Maintains physical and digital assets | Covers physical, digital, and financial aspects of assets |

| Modules included | Work orders, preventive maintenance, asset tracking | Maintenance, procurement, inventory, risk, and financial planning |

| Industries served | Manufacturing, facilities, IT | Manufacturing, utilities, healthcare, large enterprises |

| User base | Maintenance teams | Maintenance teams, procurement, finance, and operations |

| Integration | Often standalone or integrates with limited systems | Fully integrated with ERP and financial systems |

| Ideal for | Organizations needing focused maintenance tools | Businesses requiring a full asset management platform |

How is AI used in a CMMS?

CMMS is underpinned by a host of data sourced across company assets and equipment. This information gives maintenance teams critical visibility into equipment health status and targeted tools for ensuring asset uptime.

With AI, CMMS processes are being fast-tracked. In the past, CMMS required manual triggers to start work orders. These triggers were often based on schedules or user-reported issues and needed human approval.

AI in CMMS draws data from IoT sensors and software metrics to automate work order creation. Machine learning models (ML) can monitor system components and detect issues like downtime or slow performance.

It can then create tickets for resolution before or as breakdowns occur. Predictive maintenance models review historical data to spot recurring errors and forecast when software components—such as databases or application modules—are likely to fail.

With enough training, AI could autonomously adjust system settings, apply patches, and improve workflows based on software behavior. In EAM, AI could track asset use, recommend upgrades, and predict when software licenses or renewals will be needed based on asset performance.

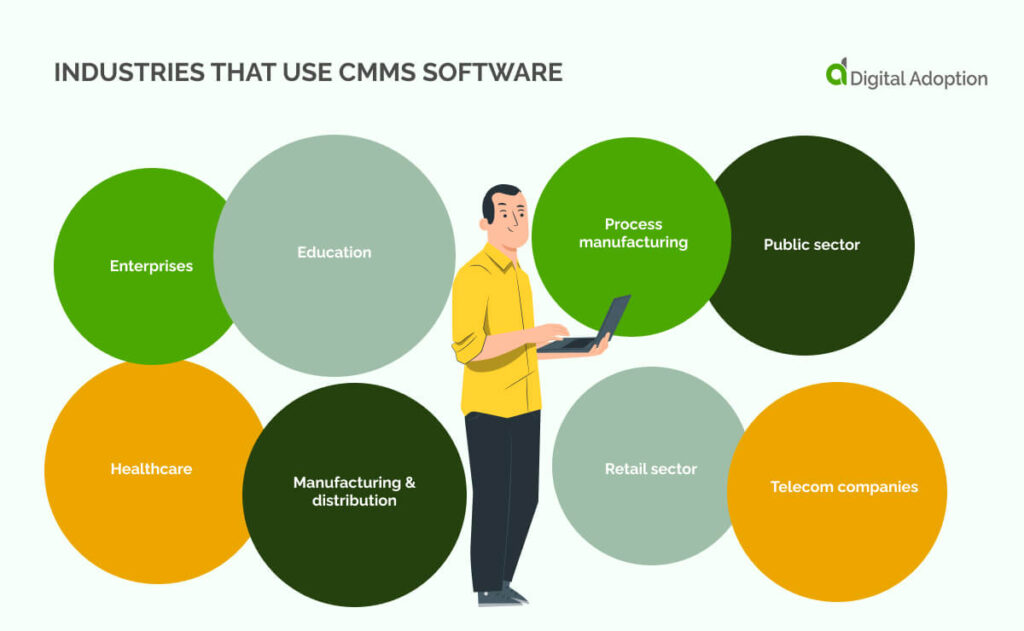

Industries that use CMMS software

We’ve gained some clarity on how CMMS differs from other maintenance management methods.

This distinction helps us understand where CMMS shines in streamlining maintenance workflows.

Now, let’s look at some industries and applications areas it proves most useful:

Enterprises

CMMS is crucial for managing enterprise resource planning (ERP) and customer relationship management (CRM) software. It tracks system performance, applies updates, and resolves bugs to avoid disruptions in operations

Education

Schools and universities use CMMS to maintain learning management systems (LMS) and student information systems (SIS). It ensures systems are updated, minimizes downtime, and manages user-reported issues for uninterrupted academic functions.

Healthcare

CMMS supports electronic health records (EHR) and hospital information systems (HIS). It ensures compliance by tracking updates and resolving glitches. The software minimizes risks of system failures that could impact patient care.

Manufacturing & distribution

CMMS maintains systems used for supply chain management, inventory tracking, and production scheduling. It automates updates and monitors software to prevent disruptions in manufacturing workflows.

Process manufacturing

In industries like chemicals or pharmaceuticals, CMMS supports production monitoring and quality control software. It ensures compliance by maintaining records and keeping systems up-to-date.

Public sector

Government agencies rely on CMMS to manage administrative platforms and public-facing systems. It ensures systems are patched and secure, enabling uninterrupted public services.

Retail sector

Retailers use CMMS for point-of-sale (POS) systems, inventory management, and e-commerce platforms. It monitors software health, resolves performance issues, and schedules necessary updates.

Telecom companies

Depend on CMMS for software that manages network monitoring, billing, and customer support. It prevents service interruptions by resolving potential problems early.

What to look for in an ideal CMMS?

IDC analysts predict that “as the number of data sources available to the asset manager continues to grow, managing, merging, and analyzing these pools of data at speed will be a tremendous challenge for EAM professionals over the next five years.”

When choosing a CMMS, focus on these key features:

- Integration: A good CMMS integrates easily with other systems, such as ERP and inventory software. This helps with smooth data sharing and reduces manual work.

- Cloud-based system: A cloud CMMS gives you access from anywhere and removes the need to maintain servers on-site. It’s scalable as your business grows.

- Mobile asset management: With mobile access, technicians can check equipment status, update work orders, and input data while on the go, saving time and improving accuracy.

- Configurability: The system should be customizable. You should be able to adjust workflows, data fields, and reports to meet your business’s needs without coding skills.

- Ease of use: The CMMS must be easy for staff to navigate. If it’s too complicated, it can lead to confusion, slower adoption, and mistakes.

- Strong vendor relationship: Choose a vendor who offers good support, training, and regular updates. This ensures the CMMS remains effective as your needs change.

- AI and data: A CMMS with AI can predict failures and recommend when maintenance is needed. Data analytics can track patterns, helping you optimize maintenance schedules and reduce downtime.

A future outlook on CMMS

CMMS will continue to be leveraged as businesses’ demand for efficiency grows.

As we know, the future of CMMS will veer further into the realm of AI. It will blend adaptive actions with predictive methods to preempt issues before they happen.

Take industry cloud platforms, which make scalability easy and data easy to access and use. Businesses will have more control over how they manage assets. CMMS will work better with other systems, fine-tuning integrated processes.

As a result, CMMS will remain essential for maintaining reliable assets and efficient operations.

Down the line, we can expect smarter, more intuitive systems that accelerate operational resilience for today’s firms.

People Also Ask

-

What is the role of a CMMS administrator?A CMMS Administrator manages the system’s setup and daily operations. They input asset data, schedule maintenance, and handle work orders. They ensure the system runs as intended and users can access it. The administrator also fixes problems, trains users, and keeps data accurate.

-

What is the price range for CMMS software?CMMS software costs vary. Small business plans range from $30 to $100 per monthly user. Larger systems with more features can cost between $500 and $2,000 monthly. On-premise versions can cost $5,000 to $50,000 upfront, depending on the system and users.

-

Which systems can be replaced by a CMMS?A CMMS replaces outdated methods for managing work orders and maintenance, such as paper logs or old software. It combines asset tracking, scheduling, and preventive maintenance into one system, making operations more efficient.