Supply chains need to run like clockwork for a business to operate successfully. Digital transformation is key to achieving this in the future.

According to MIT research, digital transformation can cut process costs in half and increase revenue by 20%.

This shift is well underway. A 2022 report by Tools Group and the Council of Supply Chain Management Professionals surveyed over 300 supply chain professionals and found that 93% of companies actively engage in supply chain digital transformation efforts.

However, the study also found that skill deficits are a primary barrier, with 53% of respondents citing it as the foremost obstacle.

Digital transformation projects are challenging. McKinsey reports a high failure rate of around 70%. That’s why laying the groundwork for supply chain digital transformation is essential.

This article explores why supply chain digital transformation is no longer optional, outlining the industries that stand to benefit the most and the best practices for a smooth and impactful implementation.

- What is supply chain digital transformation?

- Why is supply chain digital transformation necessary for business?

- What industries can benefit from supply chain digital transformation?

- What are the best practices for supply chain digital transformation?

- How can businesses implement supply chain digital transformation effectively?

What is supply chain digital transformation?

Supply chain digital transformation involves using digital technologies and data analytics to enhance supply chain performance. It can improve visibility across supply chain operations, cut costs, and mitigate potential risks.

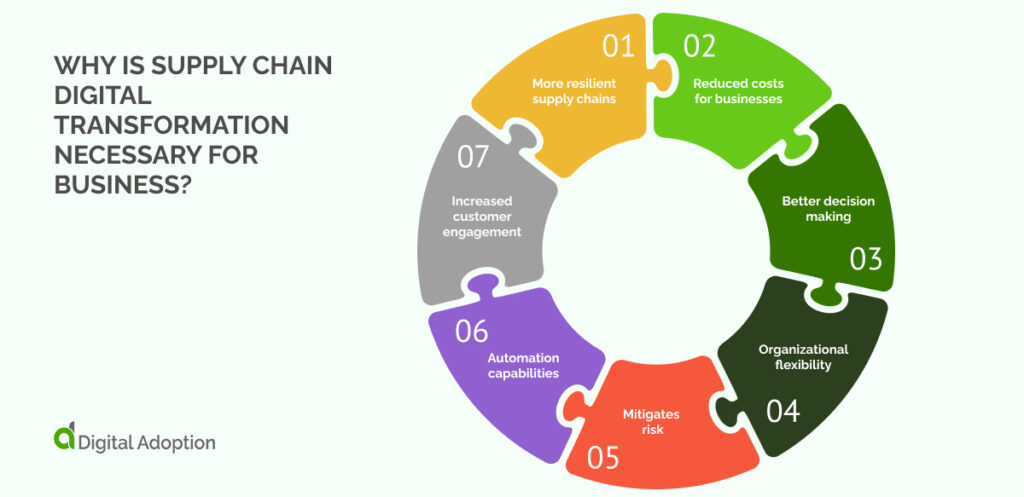

Why is supply chain digital transformation necessary for business?

There are many reasons why supply chain digital transformation is necessary for business. Below are a few key benefits.

More resilient supply chains

One key benefit of supply chain digital transformation is increased resilience. Digital transformation of the supply chain improves reliability. It also improves the traceability of the network. This enables companies to swiftly detect and respond to potential disruptions, quality issues, and more.

Business is unpredictable. Traditional supply chains are less agile and responsive to changing market conditions. However, Digital supply chains provide organizations with the tools to adapt quickly. This leads to more resilient supply chains.

This is one of the key reasons why companies across the globe are adopting digital supply chain transformation.

A McKinsey survey of supply chain executives found that 93% were taking steps to boost the resilience of their supply chains. They were doing this through digital transformation.

Reduced costs for businesses

Money is another key reason why organizations are adopting supply chain digital transformation. A versatile and efficient supply chain can increase revenue and reduce costs.

Digital tools streamline the supply chain process. It makes the supply chain more efficient, driving sales and revenue for businesses. It can also work to counter costs that may occur with traditional supply chains.

Think transportation, warehousing, and setting up a supply chain network. All of which incur significant expenses. However, issues within the supply chain can lead to even higher costs.

McKinsey’s research shows that changes in the digital supply chain can cut costs by up to 30%. The report also notes that it can reduce lost sales by up to 75% while decreasing inventories by up to 75%, further contributing to cost savings.

Gartner released another report. It shows that adding digital changes to the supply chain can raise revenue by 20% and cut costs by 50%.

Better decision making

But it’s not just about cutting costs. Supply chain digital transformation can enhance decision-making across operations too. Digital tools increase visibility and communication across the supply chain process.

Gone are the days of manually poring over reports and paper spreadsheets. Digital transformation of the supply chain gives business leaders a clear, full view of operations.

Tools like IoT sensors and RFID tags offer real-time visibility and data-driven insights. AI, machine learning, and big data analytics let digital supply chains find smart insights. They can also forecast demand accurately. They can also predict potential risks or disruptions and conduct simulations.

Research has proven the benefit of decision-making. For instance, a 2022 study based on data from 923 Vietnamese firms in cross-border trades found that knowledge intent was a key driver of supply chain digital change.

In other words, business leaders were using digital tools. They used them to understand their supply chains better. This led to better decision-making.

Organizational flexibility

Successful organizations need to adapt. It’s geopolitical troubles, global pandemics, or ships blocking the Suez Canal. Supply chain leaders must expect the unexpected. Supply chain digital transformation provides this flexibility.

Traditional supply chains are less agile. They can’t respond to market changes, demand shifts, or disruptions. Digital platforms, however, connect internal systems with external partner and supplier ecosystems. This allows for seamless information sharing. It enables coordinated responses across the network when flexibility is needed.

A recent study, which analyzed data from 255 survey responses, found that environmental uncertainty can drive digital transformation. It also explained that digital supply chains contribute to agility, flexibility, and adaptability.

Mitigates risk

Organizational flexibility and risk mitigation go hand in hand. After all, it’s easier to adapt to a certain issue in a supply chain if you’re aware of its probability.

Fortunately, supply chain digital transformation has made it easier to predict risks. And digital tools can often be more cost-effective and accurate than hiring humans to do the job.

AI and machine learning have already permeated the day-to-day operations of countless jobs. And supply chain management is no exception.

AI tools can be leveraged to accurately forecast demand and predict potential disruptions in the supply chain. Digital tools also allow for “what-if” analysis. They can even run simulations to support better decision-making and risk reduction.

These analytical tools are already being implemented in many companies’ operations today. For instance, Delta Air Lines uses a predictive analytics platform to monitor the condition of its aircraft fleet. This is just one of many ways that digital transformation of supply chains can increase flexibility, decision-making, and, most importantly, risk reduction.

Automation capabilities

Another key benefit of supply chain digital transformation in automation. Automation refers to using technology to perform tasks with minimal human interaction, which can save time and cut costs.

Digital tools automate the supply chain. They are especially useful for tasks like manual data entry, order processing, and invoicing.

By automating labor-intensive and repetitive tasks, businesses can reduce the costs associated with manual labor. This allows resources to be allocated elsewhere in the business.

But it’s not just about cutting costs and saving time. Automation can also effectively reduce the risk of human error.

According to a LinkedIn article by CONKER, approximately 80% of process deviations in well-defined industries stem from human errors. Automation can be a powerful tool for reducing human error in the supply chain while also boosting revenue for an organization.

Increased customer engagement

When it boils down to it, the customer is the most important aspect of supply chain management. Supply chain digital transformation plays a key role in increasing customer engagement.

After all, supply chain management isn’t just about getting a product from A to B; it’s also about building relationships. When customers are engaged with a supply chain workflow, they’re more likely to buy from the business again.

Digital transformation in supply chain management helps businesses understand their customer’s needs and preferences better. This understanding enables them to provide better customer service.

This benefit isn’t limited to supply chain managers. It can significantly enhance the customer’s experience as well. Online portals and other digital tools can offer customers more customized products. This boosts customer engagement and overall sales.

What industries can benefit from supply chain digital transformation?

There are many instances where supply chain digital transformation is in force today. Below are a few examples.

E-commerce industry

From the decline of shopping malls to the rise of e-commerce giants, it’s hard to think of an industry that has digitalized as much as e-commerce. According to Forbes, the global e-commerce market is expected to be worth $6.3 trillion in 2024, up from $5.8 trillion in 2023. By 2027, the e-commerce market is expected to total over $7.9 trillion.

In other words, e-commerce is big business. It’s no surprise that the sector has embraced supply chain digital transformation across its operations. A key advantage of this transformation is seen in transactions.

Today’s e-commerce is fast-paced. Secure payment gateways are integrated into the digital supply chain. They allow seamless online transactions, enable global reach, and support various payment methods.

This is backed up by a LinkedIn article by Vadim Rogov, a supply chain and operations pro. He says digital supply chains can speed up order delivery in e-commerce. It can automate order processing, packaging, shipping, and last-mile delivery.

Digital tools also give real-time visibility and transparency throughout e-commerce. This includes tracking shipments and monitoring inventory.

Example – Amazon

Amazon is a key player in the e-commerce world and arguably the most famous in the industry. The multinational giant actively uses supply chain digital transformation throughout its operations.

Its arsenal of digital supply chain tools is endless. Automation, drones, sensors, augmented reality, AI, and other advanced digital technologies are all used within its warehouses, fulfillment centers, and logistics operations. Supply chain digital transformation is necessary to keep the wheels of this mammoth brand turning.

Entertainment and media industry

Entertainment and media are other industries that have benefitted from the digital transformation of the supply chain.

The industry is expected to surpass a $1 trillion valuation in 2024. Many of these revenues now come from digital streaming platforms like Netflix and Amazon Prime.

In entertainment and media, the supply chain revolves around content. Delivering this content as efficiently to consumers’ eyes as possible is key. To achieve this, the industry has widely embraced supply chain digital transformation.

This includes adopting many digital tools. For example, modern content distribution solutions include over-the-top platforms. These platforms include Netflix and Hulu. They also include content delivery networks and live streaming services. They have digital radio and podcasts, social media, and mobile apps.

Example – Netflix

Netflix has adapted to the digital era. It did this by embracing supply chain digital transformation. This has enabled it to dominate the entertainment and media industry.

In 2007, the company shifted from a physical DVD rental supply chain to a digital streaming service over the cloud. This shift allowed the company to move away from warehouses.

According to a case study by Amazon Web Services, Netflix moved almost all its computing and storage to the AWS cloud. This includes databases, analytics, recommendation engines, and video transcoding. As a consequence, the media titan was able to deploy thousands of servers and terabytes of storage within minutes globally.

Automotive industry

This is unlike in media and e-commerce. Supply chain digital transformation in the automotive industry may not be as immediately apparent. However, digital supply chains are an asset that shouldn’t be overlooked for those operating within the industry.

Just like a car, the automotive industry consists of numerous interconnected components. The automotive supply chain is intricate, from production and transportation to finally getting the customer behind the wheel. Supply chain digital transformation enhances visibility throughout this extensive process.

Auto sales are currently in a slump. This is especially true in countries like the US. That’s why there’s a critical need for digital supply chain transformation in the car industry. Supply chain digital transformation can help cut costs and gain a competitive advantage in the market.

Digital transformation of the supply chain can also assist manufacturers in reducing business risk and becoming more agile. It can also decrease major automotive supply chain costs such as expediting, unplanned overtime, etc.

Example – Tesla

One recent example is Tesla. When faced with the 2021 global chip shortage, Tesla’s in-house software lets them rewrite code. They did this to accommodate whatever chips they could get. These digital tools provided supply chain flexibility and put Tesla ahead of the competition.

What are the best practices for supply chain digital transformation?

Despite numerous benefits, supply chain digital transformation is only effective if done correctly. Here are some of the best practices for digital supply chain implementation.

Establish a clear vision and strategy

As with any digital transformation project, establishing a clear strategy is key. This should be the first step and will serve as the foundation of the supply chain digital transformation process.

Begin by outlining a clear vision aligned with the overall organizational goals. This plan should tackle the current pain points of the organization’s supply chain and articulate how digital technologies will improve supply chain performance while enabling broader strategic objectives.

During this process, companies should take inventory of their existing supply chain resources. These assessments include evaluating employees, infrastructure, machinery, applications, and devices. Establishing a clear vision and strategy by considering the current state of the supply chain can help identify gaps and prioritize areas for digital transformation.

Develop a comprehensive transformation roadmap

Once a strategy is in place, a comprehensive supply chain digital transformation roadmap should be created. Start by establishing specific, measurable objectives that align with the overarching vision.

Quantitative objectives are common. They include improving visibility. They also cut lead times and boost collaboration. However, it’s important to note that there isn’t a rigid framework to follow. Objectives will also vary. It depends on factors like the industry, consumer base, and company culture.

Once clear objectives are established, a technology roadmap should be drafted. This roadmap should align closely with the goals. It should set dates and targets for evaluation.

It should outline physical upgrades and tech deployments. It should also cover process changes and talent/skills development. These changes are necessary to realize the transformation vision over time.

Depending on the scale of the supply chain, implementing a pilot project may prove beneficial. Instead of undertaking enterprise-wide overhauls, larger companies should start with focused pilot projects. These pilots help validate solutions, manage change effectively, and provide learning opportunities before broader rollouts.

Invest in key digital capabilities

Assessing which digital tools to invest in is important to guarantee successful supply chain digital transformation.

While supply chain digital transformation may require a sizeable upfront cost, the benefits will pay dividends in the future. However, to maximize the benefits, it is crucial to assess which digital capabilities are best suited to the business’s needs.

When selecting digital capabilities to invest in, focus on those differentiating the firm and supporting its overall business objectives. Make sure to keep in mind the long-term goals, rather than just solving current problems.

No supply chain is the same. However, popular technologies to invest in include IoT, RFID, sensors, and GPS tracking. Forecasting tools and predictive analytics are also important. These digital tools should aim to enhance data visibility and integration across the supply chain.

These digital tools provide real-time end-to-end supply chain visibility. They’re crucial for mitigating risk, making more informed decisions, and ensuring the digital supply chain runs smoothly.

Foster collaboration and trust within the workforce

Collaboration and trust among the workforce are crucial for successful supply chain digital transformation. But digital transformation is not just about technology. It’s about transforming relationships and ways of working.

Engage the workforce in digital transformation efforts. Coaching sessions and meetings can effectively build trust and communicate the importance of supply chain digital transformation.

How can businesses implement supply chain digital transformation effectively?

Supply chain digital transformation isn’t going anywhere soon; it’s here to stay. Thanks to the COVID-19 pandemic, this trend has been accelerated. A 2020 survey by McKinsey Global found that companies sped up digital transformation during the pandemic.

Supply chain digital transformation has countless benefits. It enhances visibility, reduces costs, improves risk management, and more. But it’s not an easy strategy to implement. Like any digital transformation strategy, organizations should focus on creating a plan to benefit from a digital supply chain. The plan should be measurable, match goals, and encourage teamwork.

![4 Best AI Chatbots for eCommerce [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/03/4-Best-AI-Chatbots-for-eCommerce-2025-img-300x146.jpg)

![13 Digital Transformation Enablers [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/02/13-Digital-Transformation-Enablers-2025-img-300x146.jpg)

![4 Best AI Chatbots for eCommerce [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/03/4-Best-AI-Chatbots-for-eCommerce-2025-img.jpg)